Well, here we are, mid-October already. And next weekend is Rhinebeck! It won’t be as big an occasion as last year, unfortunately, since there aren’t as many people traveling out to the festival from far-flung places this fall. Branden and I will probably drive up for the day on Saturday and meet a friend or two there, but that’s about it. Still, the occasion combined with a lack of knitting on the needles was enough to convince me to go back and edit the upper sleeve shaping on the Fall Colors cardigan.

The sweater has been finished, blocked, and in need of tweaking for almost a year now. I didn’t quite finish it in time for Rhinebeck last year, and then the upper arms ended up a teensy bit tight for comfort in the final fit. I put it aside, but never got back around to fixing those sleeves.

Finally, I pulled it out, snipped a stitch, and pulled out the upper sleeve shaping. Let me tell you, there is no chance of running stitches around those steeks. Even the sleeve yarn that was simply knit together had felted to itself like glue after only one blocking, and it was a real pain to pull out the 4 inches of sleeve that needed to be reknit. Fortunately, I had extra yarn, as most of the original yarn didn’t survive the ripping process. The ripping was done, though, and the upper sleeves were reknit with more gradual decreases and a little more length, and the sweater is back together again. Minus a couple of ends to weave and a blocking, it might finally be done.

Or, it might not be.

I had planned this sweater as one with set-in sleeves, and did sleevecap shaping accordingly. Now that the upper arms are fitting more loosely, though, it’s looking more like a drop-shoulder fit. The colorwork at the shoulders is about 3/4 to 1″ wider than my shoulders, so it hangs off just a little bit. This isn’t a problem overall, but it means that the sleeves really should be knit for a drop-shoulder and not a set-in sleeve.

As a consequence, the shoulder looks oddly triangular rather than rounded.

The photo above is on the dress form, and is less distorted because she wasn’t contorting around to take pictures of herself in a mirror. Of course, she doesn’t have full arms, so it’s a little hard to see how the sleeve will hang when it’s on her. Here’s the best I could get in the bathroom mirror, with the sweater on myself.

I’m twisting my shoulder around to be able to take the picture here, so it’s not a great shot, but I think you get the idea. That extra shoulder shaping relieves tension on the colorwork body above it, and distorts the body edge out of shape.

I am trying to decide whether this will make me crazy or not (or, rather, whether it will make me crazier than redoing the sleeve cap yet again). Of course, some of the stitching will mold itself into to the correct shape again with blocking, but I don’t want to block until I’m sure I’m done, especially after the felted ripping from last time.

My gut feeling says that it’s time to rip it out, but then my common sense pops up to remind me that sometimes the perfect is the enemy of the good. And so, the Fall Colors sweater is back in time out while I think over what to do with it, yet again.

In better news, the moebius infinity cowl is off the needles, after many months of train knitting. One ply of the yarn is from Fiber Optic, and I dyed the other to match it. I had about 700 yards of laceweight yarn, and just kept knitting until I ran out. I cast on 400 stitches (for each half of the moebius) on size 1’s, which gave me a final size of just under 5 feet after blocking, and it’s about 14 inches wide.

I wasn’t sure how I’d feel about a moebius cowl. I’m not a shawl or a cape type (much as I’d love to be!), but I do love scarves, and a long cowl like this falls somewhere in between. I knit the garter stitch circular scarf this summer in a heavier-weight yarn, but haven’t fallen in love with it yet. I’ll probably wear it around the house a lot this winter, but I was hoping for something that I could wear to work.

The moebius cowl is knit at a much finer gauge, and so has a lot more drape than the garter stitch scarf. The moebius twist also helps it lay flat more comfortably when doubled up, as I have it shown above. As it turns out, I love it.

It works equally well wrapped once or twice, and it stays nicely out of the way most of the time. It’s lightweight enough to be easy to carry, but the wool and silk make it very warm. The width means that I can pull it down over my shoulders, but it’s not too bulky to use as a scarf, either. The fine gauge makes it feel dressier to me, and I love how the colors work together.

I like it so much, in fact, that I’ve cast on for another.

This yarn is the BFL top that I dyed just before we left Seattle to use up the last of my liquid dyes, rather than packing them up for the move (a sure recipe for disaster). I spindle-spun the yarn in Germany, and got about 950 yards of laceweight. The color varies from a sapphire blue to a spruce green, and it’s been sitting in my stash just waiting for the right project to show it off. I wanted something simple enough to let the colorwork be the focus of the garment, and also something very wearable. A second moebius seems like just the thing.

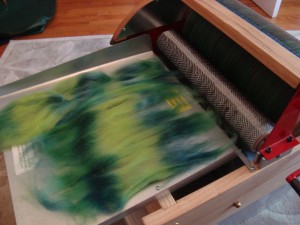

In between knitting projects, I’ve also been whiling away the time spinning up the blended batts that I made a couple of weeks ago. I plied the first skeins yesterday.

Yet again, it seems that I have created greens and blues that are impossible to capture with a camera. The yarn looks a little grayish and washed out in the photos above, but it’s really quite a saturated blue-green. The camera is picking up strongly on the grays in the olive green, and seems to ignore the saturation of the other two colors.

If I had this yarn to spin over again, I think I might use a very saturated spruce green as the third ply, to give the brighter green something to pop out against a bit more. That would move the yarn solidly into the jewel tone range, and would really make it glow. I like the yarn with the olive well enough, but the other would be more dramatic. On the plus side, having that olive in there will help a garment knit from this yarn to coordinate equally well with jewel and earth tones, which is an important feature in my wardrobe. With the spruce in there, I’d probably only wear this with black or with very dark brown. With the olive, I could get away with a lighter brown, a khaki green, or even a gray just as well as with black.

So far, I have about 600 yards of fingering to DK weight yarn in the two skeins, before wet-finishing the yarn. My guess is that it will bloom up a bit to be closer to the DK weight by the time I’m done. Â There are a few more ounces left on the bobbins, but it seems that I’m getting different grists from the three batts, so I will probably fill the bobbins again before plying off the third skein, to minimize breaks in the yarn. The light green and the teal are Falkland, I believe, and the olive is Polwarth, and it seems that spinning three plies of the same diameter leaves me with less length in the olive than the other two. I’ve run into this before when combining different breeds of wool in one project, and it probably means that I’ll have extra of the teal and green left over at the end.

The same thing happened with my hand-dyed Rambouillet and the Fiber Optic silk-BFL in the yarn I used on the moebius cowl above. Both fibers started out as 4 oz, and the brown ply was actually spun a little thicker than the silk, but I ended up with quite a bit of brown left over on the bobbin when I was finished. I left it on the bobbin unplied, just waiting to see what it might turn into. This turned out to be a good thing in the end, since I forgot to switch to a garter stitch edging to keep the shawl from rolling until the very end, when I ran out of the mixed-ply yarn. I could have pulled back 8 or 10 rows, but that would have involved picking up 800 stitches of laceweight, and was not a recipe for fun. Instead, I went back and plied up the leftover brown singles, and used those to make the garter stitch edging instead.

I have a total of 24 oz of fiber in the 6 blended batts, and I’m hoping that I’ll have enough yarn for a sweater in the end (at my current grist of ~74 yd/oz, I should get about 1700 yards, which will be plenty!). If I do end up with extra of the two stronger colors, plying them on themselves will make great accent yarns for edging and other design features.